Underbase Grouting

FoundOcean gained initial experience in underbase grouting on the Thistle SALM installation project in 1978. The scope of work included pumping 2,000 tonnes of hematite into the base of the structure.

Gravity structures range widely in size and weight, and are constructed from either reinforced concrete or steel. When the structure is first set down on the seabed, the uneven profile of the seabed results in uneven contact with the underside of the structure. Support occurs only at the high points, with voids where the seabed is lower. This uneven support can lead to unacceptable structural loads. In order to provide a firm, even support to the underside of a gravity structure, a cement grout is pumped into the void between the seabed and the structure.

The ideal grout simulates the seabed soil, with a low compressive strength and even consistency. FoundOcean uses low strength grouts, with 28 day strengths as low as 2MPa.

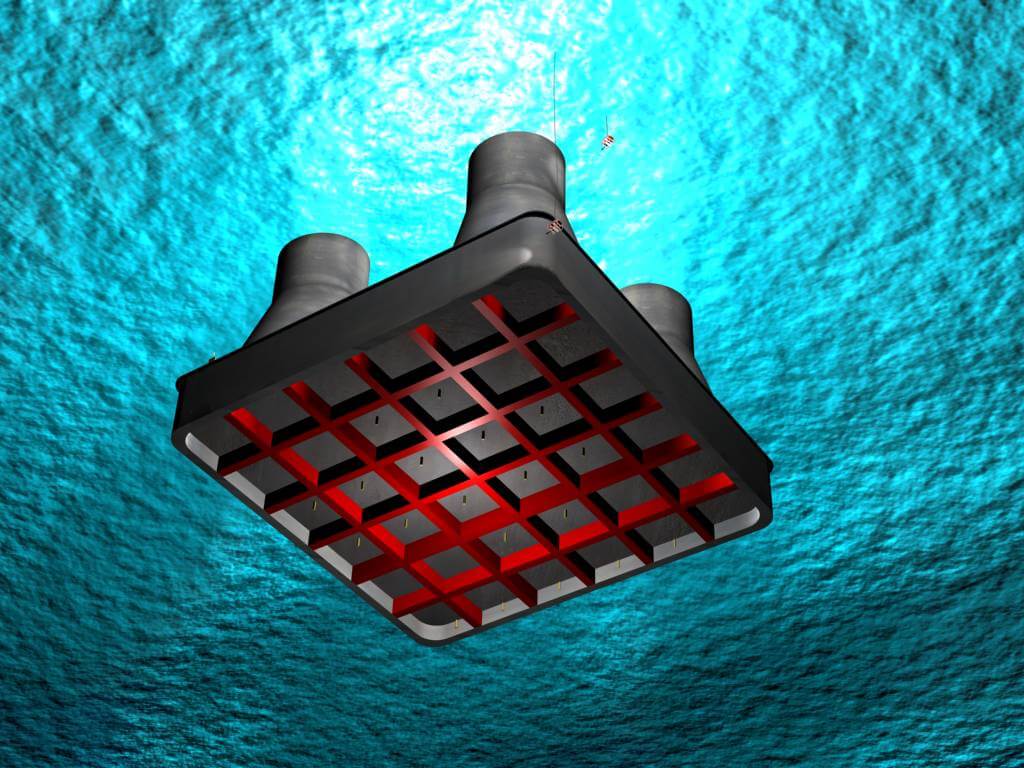

The underside of the structure is normally divided into compartments which are grouted individually. This ensures proper and complete filling of the voids beneath the structure. Each individual compartment is equipped with fill and vent lines. The fill lines may run to a surface manifold, or terminate at a subsea ROV grout connector. As well as acting as an outlet, the vent lines show when the compartment is completely filled.