Strengthening the Valhall Quarters Platform (2010)

The Valhall Quarters Platform was installed in 1979. Due to regulation changes, the jacket needed upgrading to increase its strength and resistance to freak waves. To achieve this, the four legs of the jacket were injected with grout from sea level up to the cellar deck.

Aggregate-based grout was used to reduce the heat of hydration when curing, which would otherwise have been excessive due to the large volume of grout being placed. Heat of hydration is the heat generated due to the chemical reaction which takes place when water is added to the cement. The heat causes the grout to initially expand, and then contract as it cools, which could lead to the grout cracking. Excessive heat generation is the result of very large grout volumes with high cement content.

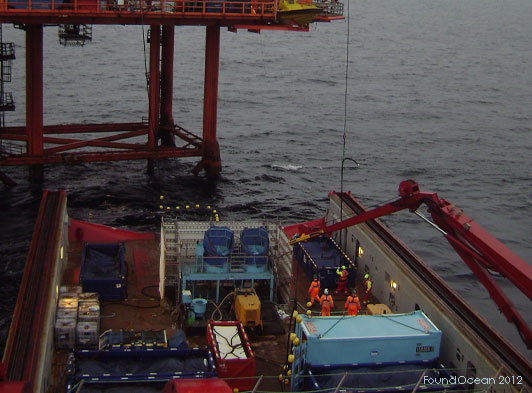

The platform was prepared for grouting by the client. This involved installing the hose handling equipment, drilling the holes for the connectors, inspecting the legs and fitting the valves. FoundOcean then worked from a construction vessel to mix and pump the grout to the platform legs.

Grout was pumped from the bottom of the jacket leg to the top, a distance of 44.25m and volume of approximately 20m3. This was repeated for each leg. Sample cubes were taken to measure grout strength at 24 hours, three days and 28 days.